WG S350 UltraFlexible Printing Setup

1.Flexible print head combinations: Various combination choices to fit different requirements.

2.Max print speed up to 75m/min, balancing high efficiency and adaptation to various applications.

3.Max print width up to 310mm, expanding application range, better fulfilling different needs.

online service

1. Flexible print head combinations: Various combination choices to fit different requirements.

2. Max print speed up to 75m/min, balancing high efficiency and adaptation to various applications.

3. Max print width up to 310mm, expanding application range, better fulfilling different needs.

Main Technical Parameters

| Model | WG S350 Pro Series |

| Print control | Piezoelectric print head, grayscale printing |

| Print head resolution | 600600 / 900600 / 1200*600 optional |

| Print speed | High - precision: 30m/min (1200600); Normal: 45m/min (900600); High - speed single - point: 60m/min (600*600) |

| Print data | Fixed label data, partially variable data (optional) |

| Print head model | Epson S3200/U1/U3 |

| Ink type | UV ink |

| Color configuration | Cyan, magenta, yellow, black, white, varnish, spot color (optional) |

| Ink tank size | 5L/color |

| Medium system | - |

| Reel system | Servo drive, tension detection, paper break protection, roll diameter detection, etc. |

| Reel specification | Maximum roll diameter 700mm |

| Digital medium thickness | 0.04 - 0.35mm |

| Effective printing width | 350mm |

| Dust removal method | Contact - type double - sided dust removal system |

| Static elimination system | Static elimination rod |

| Maximum web width | 360mm |

| Drying system | Efficiency enhancement (optional), ink + white (optional), one color one curing; CMYK spot color, two colors one curing LED drying system |

| Pre - curing drying | - |

| Total curing drying | Overall curing of the whole machine |

| Cleaning system | Automatic cleaning system |

| Data cleaning unit | - |

| Data transmission | Internet network transmission |

| Data interface | Visualized simplified UI interface |

| Specification | - |

| Length 脳 Width 脳 Height | 680022002100mm |

| Floor area | 18 square meters |

| Installation conditions | - |

| Environmental requirements | Temperature: 25 - 30鈩? Humidity: 50 - 65% |

| Power supply specification | AC 380V, three - phase; Maximum power: Main machine 25KW, UV 20KW |

| Air supply requirement | Drying industrial air source 0.6MPa |

Sharp and Refined Printing Quality

1. Adopts single-pass method, contactless printing allowing single pass without the need of plate making.

2. Max print resolution up to 1200*1200dpi, delivers print with exquisite detail and vibrant color.

User-friendly Operation

1. Highly integrated software enables rapid order taking and short run job.

2. Touch screen interface allowing easy access and operation.

3. Simplify maintenance with automatic cleaning, moisturizing, and print head collision avoidance.

4. Compact model requesting minimal floor space, suitable for various applications.

Reliable printing quality

1. Equipped with high precision, long durability piezo print head.

2. Consistent printing quality that supports 24/7 production.

Welcome to our website! Please send your words at any time in the following form and ask us, we will contact you and provide you with the corresponding service as soon as possible. Please write in English.

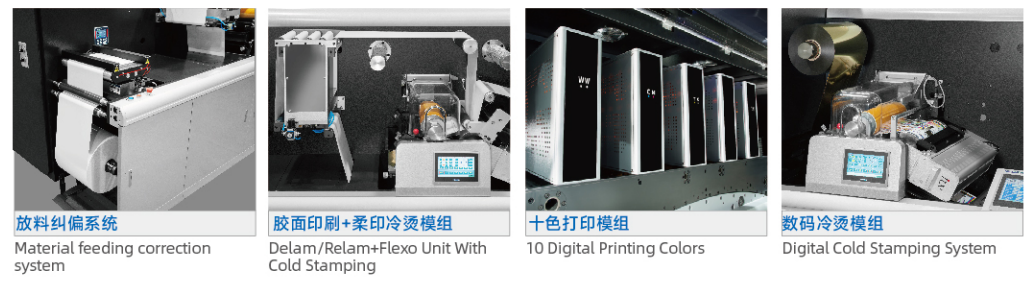

ZJR S350 Pro Hybrid (Flexo/Digital) Printing Machine

1. The whole machine adopts the latest servo control system and each printing unit is driven by independent servo motor, which ensure the accurate registration during high speed production.

2. The printing roller adopts sleeve type without gear which is light, easy, convenient and fast to change. This type of design is largely improve the printing quality and reduces the maintenance.

3. Motorised pressure adjustment system between anilox roller to plate and plate to substate makes the pressure setting very easy and fast, which greatly improve the efficiency.

WG S350 UltraFlexible Printing Setup

1.Flexible print head combinations: Various combination choices to fit different requirements.

2.Max print speed up to 75m/min, balancing high efficiency and adaptation to various applications.

3.Max print width up to 310mm, expanding application range, better fulfilling different needs.

WG S350 Digital Printing Machine

1. Print heads combination are flexible: multiple combination per requirements;

2. Max print speed up to 60m/min which is high efficiency and suitable for variable job application;

3. Max print width up to 350mm which expands application range and increases flexibility.

Manual Inspecting Machine EM-320/450

EM-320 inspecting machine is an accessorial machine for printing machine and die-cutting machine; it inspects the quality of printing and die-cutting manually.

This machine has meter counting and label counting function, it has the characteristics of stable running, easy operation, high speed and forward-backward running/inching.