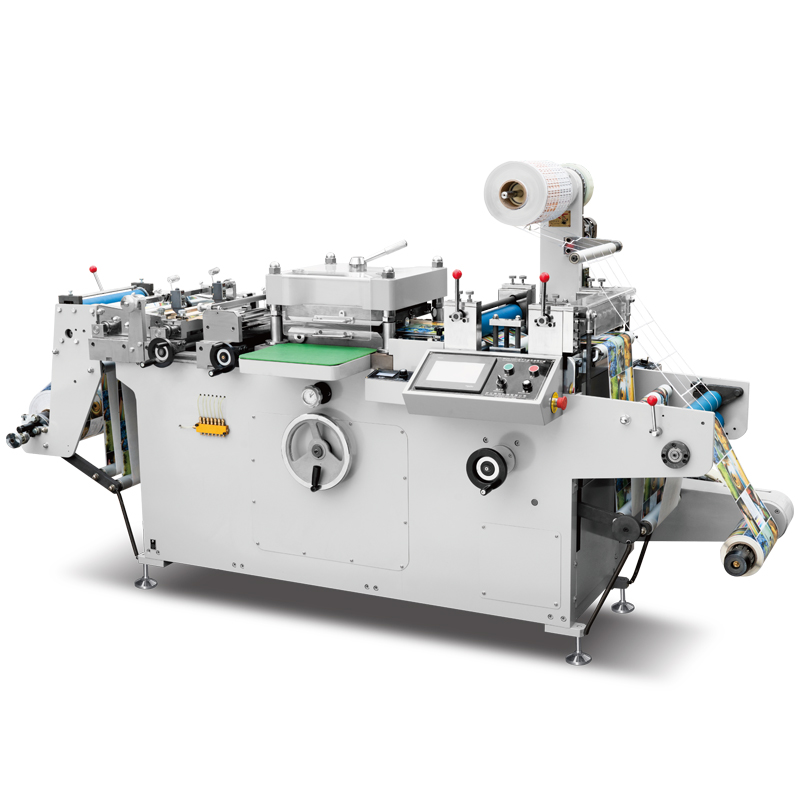

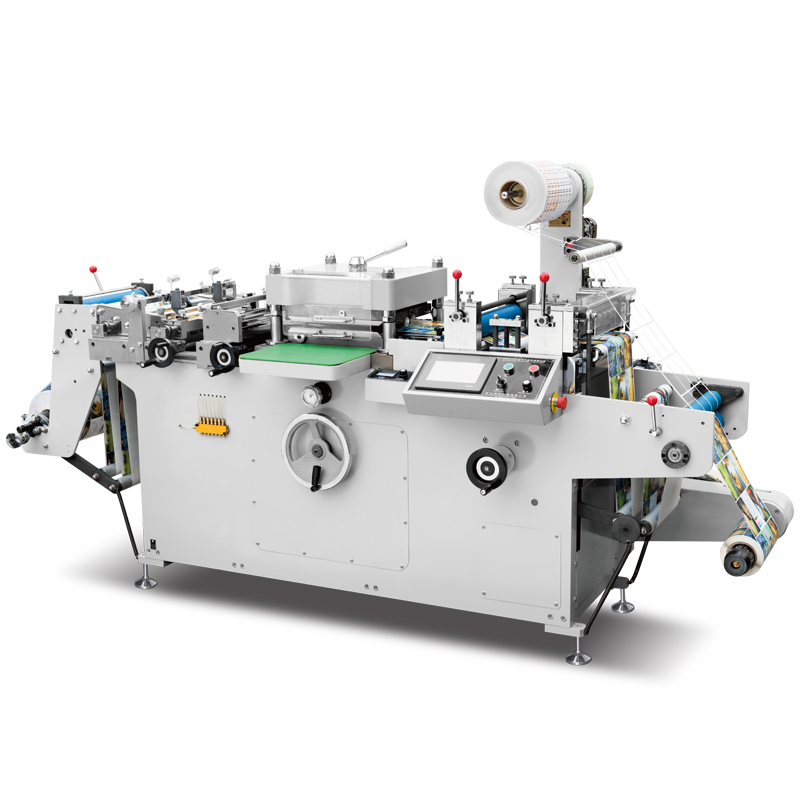

Flat-bed Label Die-cutting MachineWQM-320G/420

This machine adopts accurate flat die-cutting system, controlled by servo motor.

Two sensors are used to control the web-guider and one sensor to follow the registration mark. It's suitable for die-cutting of all kinds of adhesive labels and hologram labels. It's the ideal converting machine for flexo printing machine, screen printing machine and gravure printing machine.

online service

Two sensors are used to control the web-guider and one sensor to follow the registration mark. It's suitable for die-cutting of all kinds of adhesive labels and hologram labels. It's the ideal converting machine for flexo printing machine, screen printing machine and gravure printing machine.

Main Technical parameters

|

Model

|

WQM - 320G

|

WQM - 420

|

|

Cutting speed

|

20 - 280 (rpm)

|

20 - 280 (rpm)

|

|

Max.unwind diameter

|

500mm

|

500mm

|

|

Max.web width

|

320mm

|

420mm

|

|

Max.die - cutting width

|

300mm

|

400mm

|

|

Max.die - cutting length

|

300mm

|

400mm

|

|

Accuracy

|

±0.15mm

|

±0.15mm

|

|

Total power

|

3.5kw

|

4.5kw

|

|

Power supply

|

220v±10%

|

380v

|

|

Machine weight

|

(about) 1700kgs

|

(about) 2300kgs

|

|

Dimensions(L×W×H)

|

2600*990*1400mm

|

2950*1350*1400mm

|

Welcome to our website! Please send your words at any time in the following form and ask us, we will contact you and provide you with the corresponding service as soon as possible. Please write in English.

Adhesive Label(logo) Die-cutting Machine WQM-320G/420

This machine adopts accurate flat die-cutting system, controlled by servo motor.

There are two sensors to control the web-guider and one sensor to follow the registration mark. It’s suitable for die-cutting all kind of adhesive labels and hologram labels. It’s the ideal converting machine for flexo printing machine, screen printing machine and gravure printing machine.

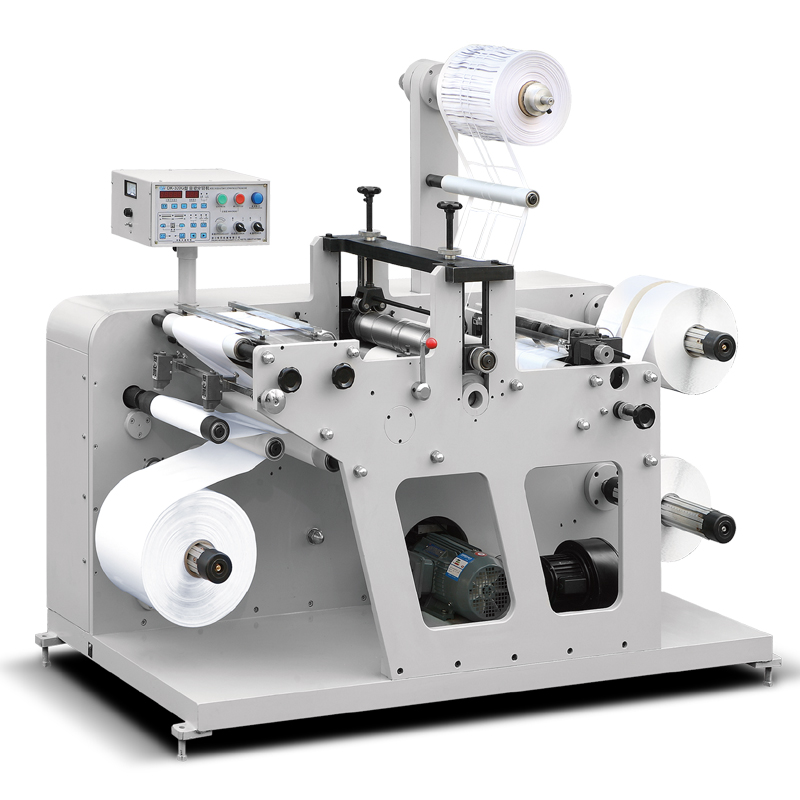

Slitting Machine with Rotary Die-cutting Station DK-320G/450G

DK-320G Slitting machine with rotary die-cutting function is upgraded from DK-320 slitting machine, it is equipped with high accuracy rotary die-cutting system. This machine is suitable for blank adhesive labels. Die-cutting, laminating (optional), slitting can be finished in one process. It has the function of automatic meter counting, automatic stop and web guiding by photocell. The machine has the characteristic of compact structure, fast speed, high efficiency, easy operation, accurate slitting and steady running etc.

Learn MoreFlat-bed Label Die-cutting MachineWQM-320G/420

This machine adopts accurate flat die-cutting system, controlled by servo motor.

Two sensors are used to control the web-guider and one sensor to follow the registration mark. It's suitable for die-cutting of all kinds of adhesive labels and hologram labels. It's the ideal converting machine for flexo printing machine, screen printing machine and gravure printing machine.

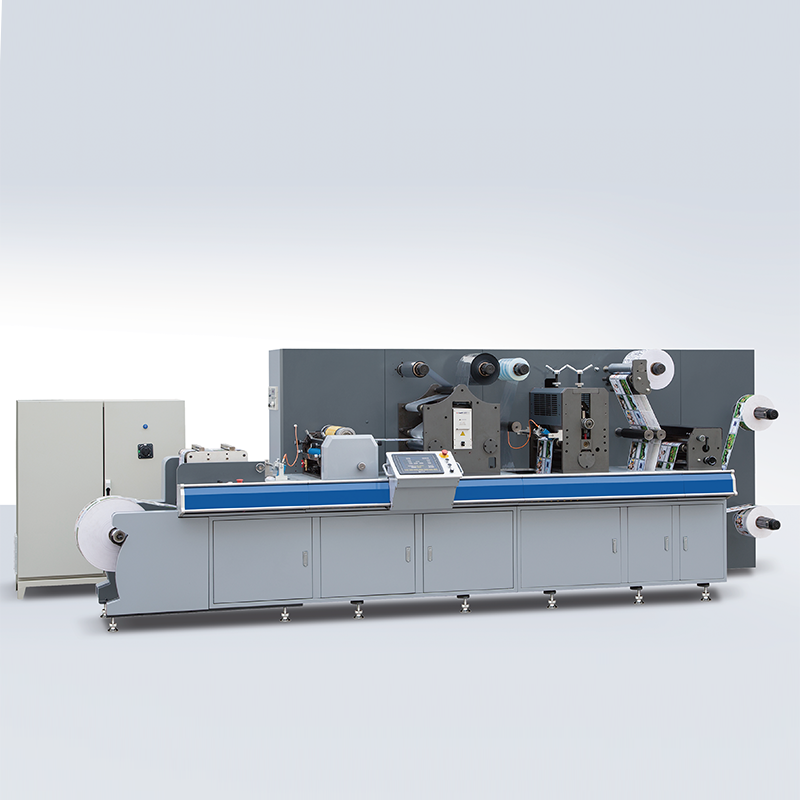

Rotary/Semi-rotary Label Die-cutting Machine ZM-320

ZM-320 rotary/semi-rotary label die-cutting machine is a converting machine equipped with inline slitter. This machine adopts latest Rexrtoh-Bosch (Germany) servo motors and control system, including: unwinder, web-guider, lamination, register die-cutter, slitter and dual rewinder.

Learn More