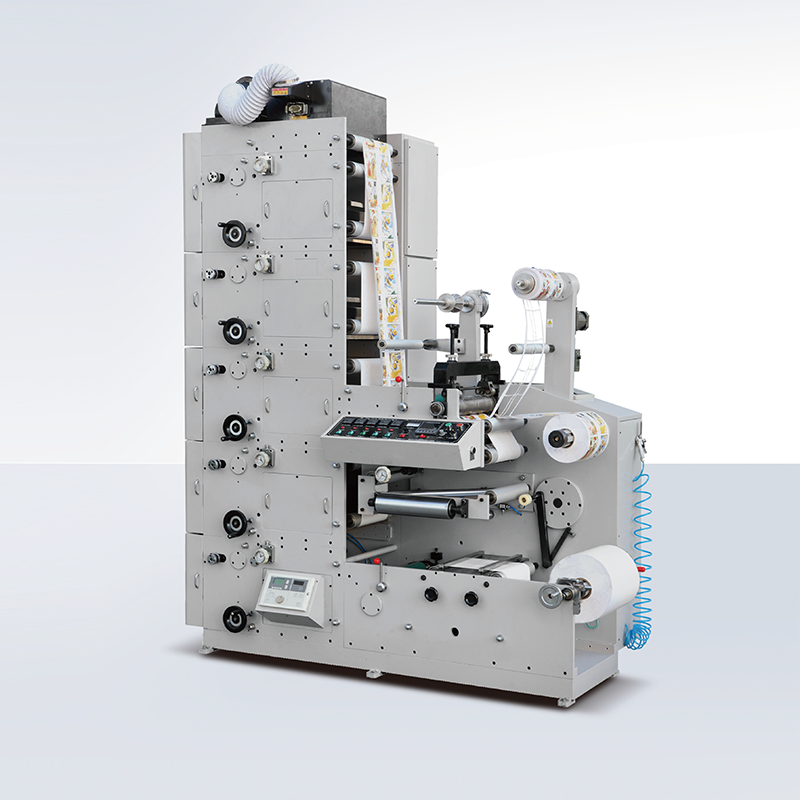

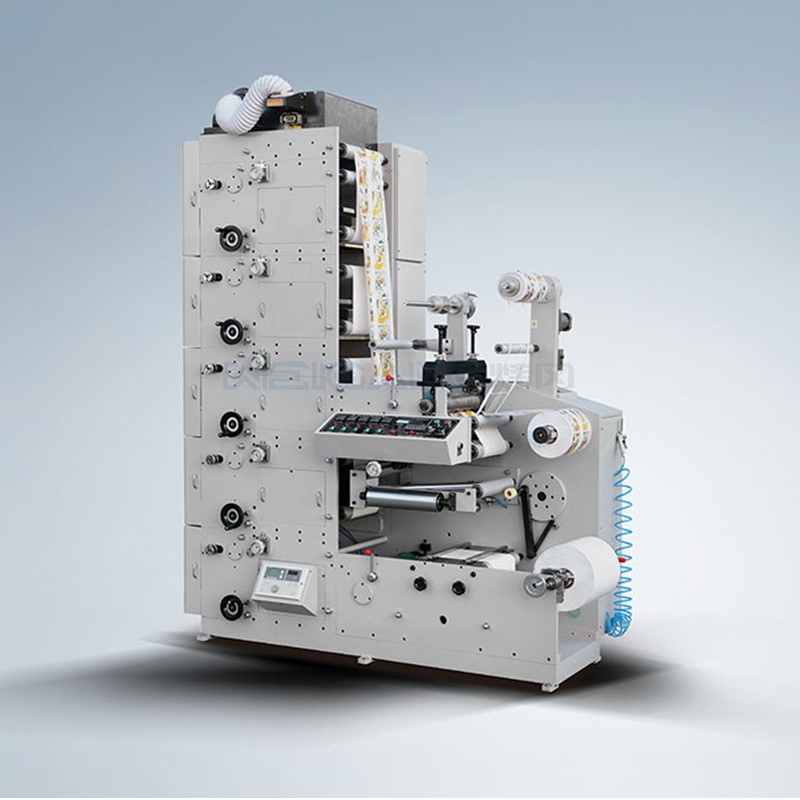

Hybrid (Flexo/Digital) Printing Machine-ZJR-S350-Pro

1.The whole machine adopts the latest servo control system and each printing unit is driven by independent servo motor, which ensure the accurate registration during high speed production.

2.The printing roller adopts sleeve type without gear which is light, easy, convenient and fast to change. This type of design is largely improve the printing quality and reduces the maintenance.

online service

1. The whole machine adopts the latest servo control system and each printing unit is driven by independent servo motor, which ensure the accurate registration during high speed production.

2. The printing roller adopts sleeve type without gear which is light, easy, convenient and fast to change. This type of design is largely improve the printing quality and reduces the maintenance.

3. Motorised pressure adjustment system between anilox roller to plate and plate to substrate makes the pressure setting very easy and fast, which greatly improve the efficiency.

4. Printing film equips with water chiller drum, which ensure the good and stable printing on unsupported material.

5. Suitable for printing variety substrates, such as paper, all kinds of adhesive material, unsupported film (PET, OPP, CPP, PP), cardboard and so on.

6. Equips with high-precision Piezo print head, multiple printing resolution are available (1200600 / 900600 / 600*600).

7. Adopts single pass solution, non-contact print.

8. CMYK + special effect + white (optional).

9. Automatic cleaning, moisturizing, and print head anti-collision, makes machine easy and simple maintenance.

10. Supports variable data printing. The printing machine hybrids with flexo and digital meet the application of label with variable data, suitable for very short run to long run job.

| Model | ZJR S350 Pro Series |

| Print control | Piezo print head, grayscale printing |

| Print Resolution | 600600dpi / 900600dpi / 1200*600dpi optional |

| Print Speed | High - resolution mode: 30m/min (1200600) |

| Normal mode: 45m/min (900600) | |

| High - speed mode: 60m/min (600*600) | |

| Max speed of flag printing | 18m/min |

| Print Data | Variable data (variable two - dimensional code, variable barcode data, etc.) / fixed label data |

| Print head model | Epson S3200U1/U3 |

| Ink | UV ink |

| Ink type | UV ink |

| Ink color | Cyan, magenta, yellow, black, white, varnish |

| Ink tank | 5L per color |

| Substrate system | - |

| Unwinder/rewinder | Servo drive, tension detection, paper break protection, roll diameter detection, etc. |

| Max unwinder/rewinder dia | Maximum roll diameter: 500mm |

| Substrate thickness (digital) | 0.04 - 0.35mm |

| Max print width | 350mm |

| Web cleaner | Double - sided contact type dust removal system |

| Static eliminator | Static rod |

| Max web width | 360mm |

| LED dryer | CMYK (optional), spot color, white (one color) - one - color curing |

| CMYK + special effect - two - color curing | |

| CMYK + varnish - two - color curing | |

| Complete curing | UV drying and then varnish curing |

| UV ink and pantone: 1 - color UV dryer | |

| Cleaning system | Auto cleaning system |

| Data transfer | Optical fiber interface |

| Connector | Optical fiber interface |

| Control panel | Visual simple UI interface |

| Dimensions | 1400025002500mm |

| Floor space | 37 m簡 |

| Installation conditions | - |

| Surroundings | Temperature: 25 - 30 degrees; Humidity: 50 - 65% |

| Power supply | 380V, 3 - phase, rated power: 15KW(Inkjet printer: 3.5KW; LED/UV for inkjet: allow 0.04Mpa) |

| Air supply | Dry industrial air source 0.6MPa |

Welcome to our website! Please send your words at any time in the following form and ask us, we will contact you and provide you with the corresponding service as soon as possible. Please write in English.

Hybrid (Flexo/Digital) Printing Machine-ZJR-S350-Pro

1.The whole machine adopts the latest servo control system and each printing unit is driven by independent servo motor, which ensure the accurate registration during high speed production.

2.The printing roller adopts sleeve type without gear which is light, easy, convenient and fast to change. This type of design is largely improve the printing quality and reduces the maintenance.

Stack Flexo Press ZBS-320/450

1. Adopts the ceramic anilox cylinder to transfer the ink.

2. Unwinding and rewinding are controlled by magnetic powder brake/clutch.

3. Each printing unit adopts 360°plate adjustment.

ZJR-350E/450E/650E

1. The whole machine adopts the latest servo control system with each printing unit driven by an independent servo motor. There are 23 servo motors in total (8-color machine), ensuring accurate registration during high speed running.

2. The printing roller adopts sleeve system which is light, easy, convenient and fast to change. This type of design significantly improves the printing quality and ease the maintenance burden.

Label(logo) Flexo Printing Machine ZBS-320/450

1. Adopt the ceramic anilox cylinder to transfer the ink.

2. Unwinding and rewinding are controlled by magnetic powder brake/clutch.

3.Each printing unit adopts 360°plate adjustment.

4.Each printing unit equips with hot air dryer.

5.This machine with one die-cutting station, which makes printing and die-cutting can be finished in one process.